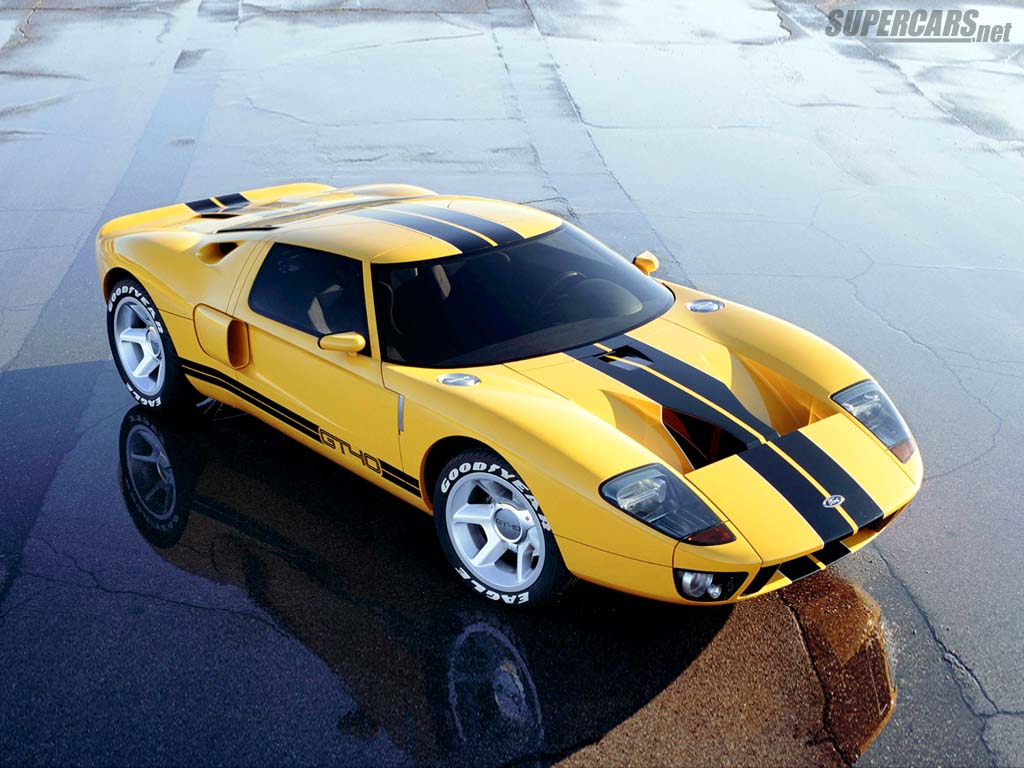

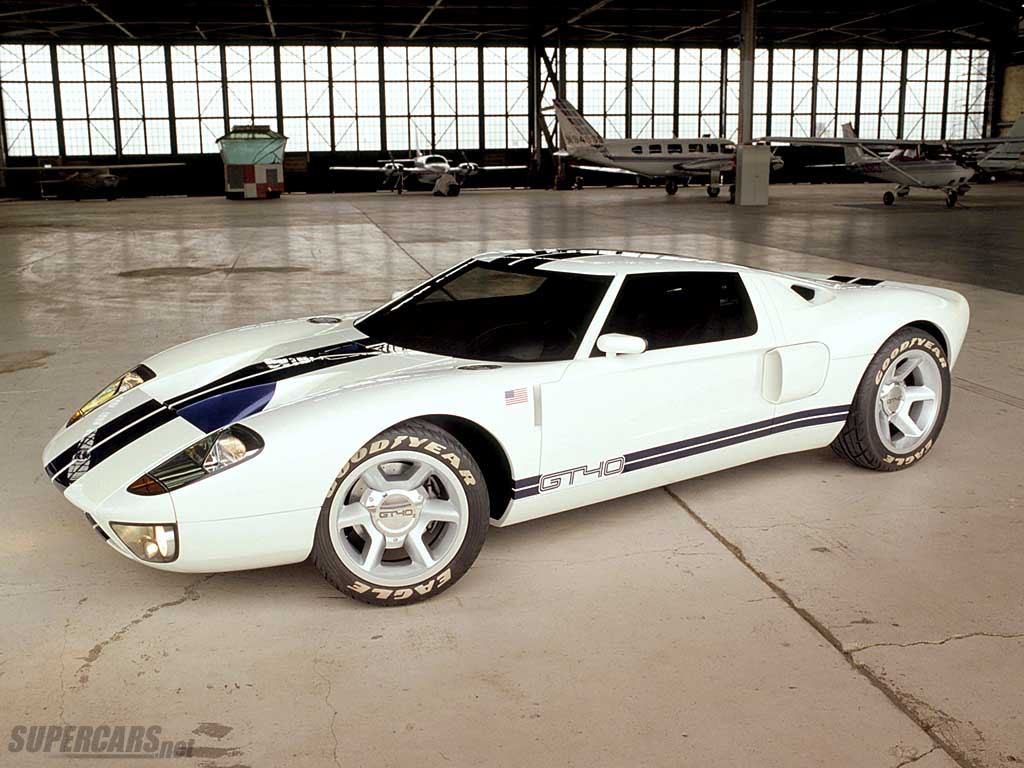

2002 Ford GT40 Concept

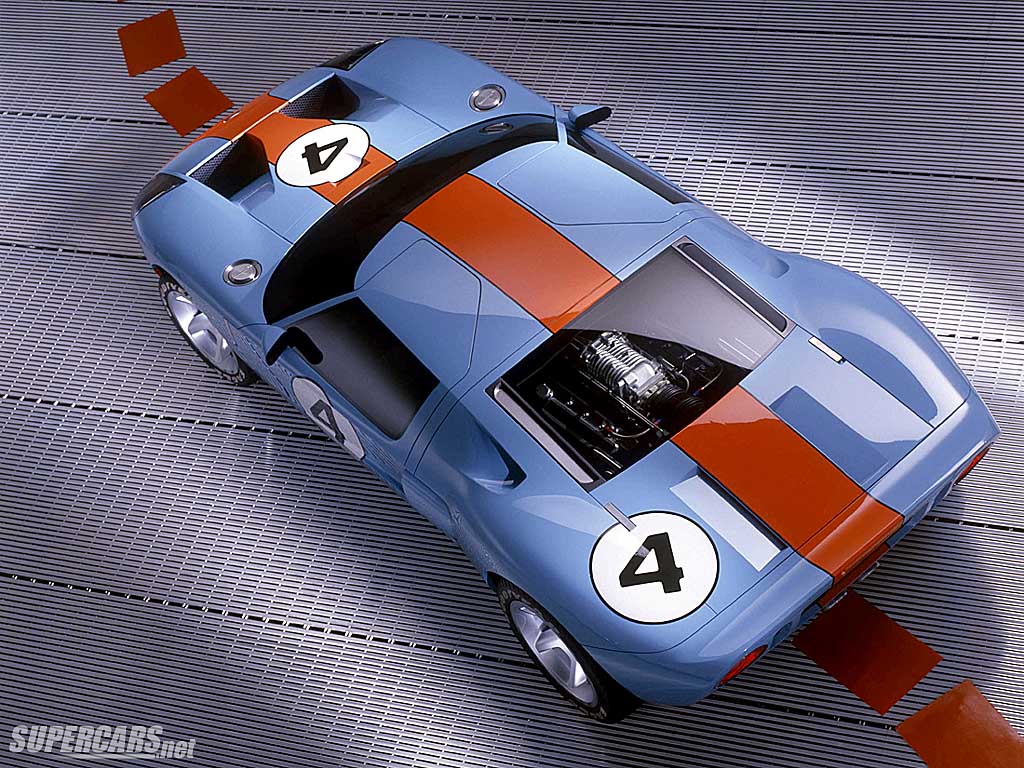

Released at the 2002 North American Auto Show, Henry Ford II was proud to show off a modern-day version of Ford most successful endurance racer. A month after the release, Ford announced the GT40 would be put into production and with a price ‘around six figures’.

Ford Press Release:

The GT40 finds new life in a modern road car that re-ignites Ford’s passion for racing. This new high-performance concept is inspired by the vehicle that roared into the hearts of car enthusiasts everywhere during the 1960s. While the new concept represents the best of Ford design, engineering and expertise this is a no-frills machine. ‘No voice-activated telematics here, not even power windows. Just pure, refined performance’ said Jay Mays, Ford’s vice president of Design.

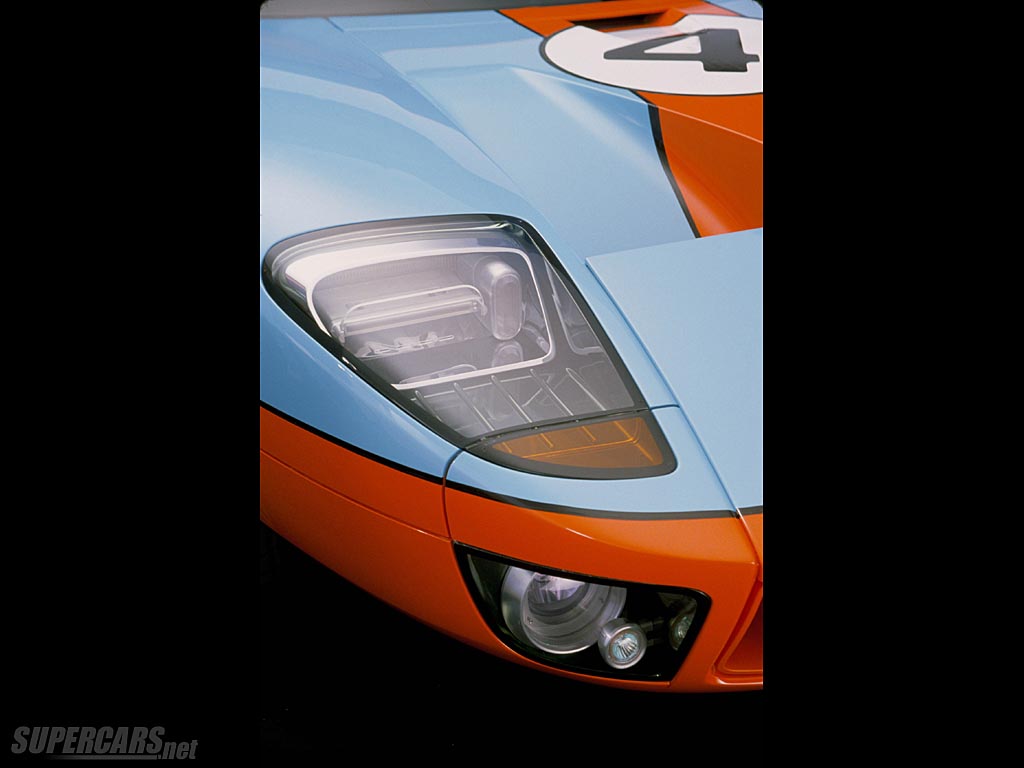

The GT40 Concept casts a familiar, sleek silhouette of its predecessor, yet every dimension, every curve and line on the car is a unique reinterpretation of the original. The GT40 features a long front overhang reminiscent of 1960s-era racecars. But its sweeping cowl, subtle accent lines and fiber-optic headlamps strike a distinctly contemporary pose. Its new lines draw upon and refine the best features of GT40 history and express the car’s original identity.

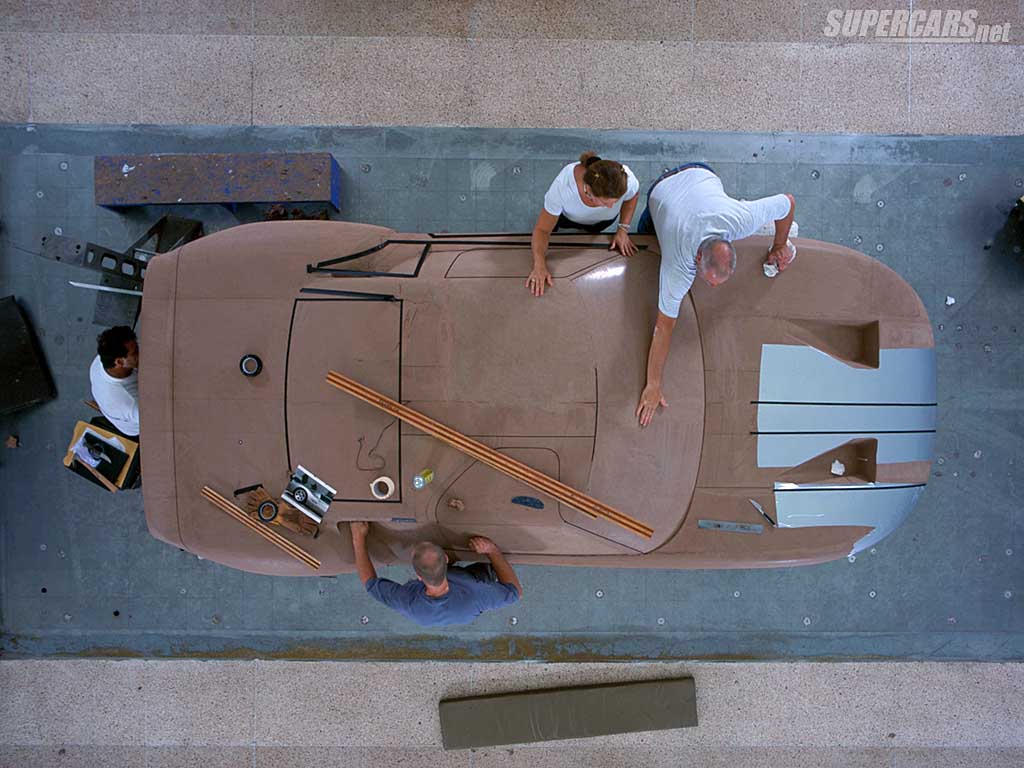

To ensure that the vehicles mechanicals met with the expectations that would be required of a vehicle bearing the GT40 name, Ford turned to Special Vehicle Team Engineering. SVT engineering chief John Coletti and vehicle engineering manager Fred Goodnow led the project from its inception.

Chassis

As on the historic car, the composite body panels are unstressed. Instead of steel or honeycomb-composite tubs used in the 1960s, Ford’s SVT Engineering group developed an all-new aluminum space frame as the foundation for the GT40 concept. Constructed of extruded sections and aluminum panels, the space frame provides a rigid foundation for the engine and driveline while permitting the use of the specially fabricated composite body panels. The space frame consists of a central cabin section, a front suspension sub-section, and a rear powertrain-chassis cradle, bolted together for rigidity.

While the original GT40s owed their chassis stiffness to a pair of beefy sills that doubled as fuel reservoirs, the new concept relies on a single center tunnel for its backbone. While greatly improving entry and exit, it has the added benefit of providing a structurally secure location for the fuel supply.

The concept’s suspension has been fabricated almost entirely from scratch. The layout, front and rear, uses unequal-length control arms and a push-rod/bell-crank system to interface with the horizontally mounted spring-damper units. Mounting the spring-damper units horizontally allowed the designers to achieve the characteristic low-slung GT40 profile.

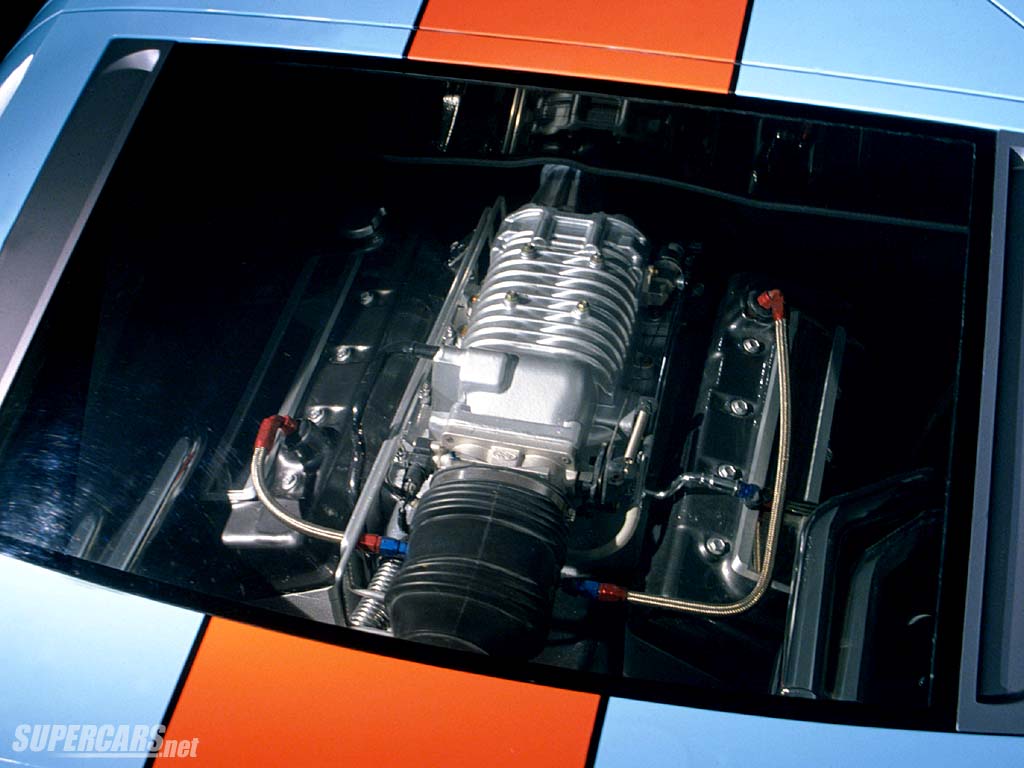

Braking is handled by six-piston, aluminum Alcon calipers with cross-drilled and vented rotors at all four corners. When the rear canopy is opened, the rear suspension components and engine become the cars focal point. Precision-milled aluminum suspension components and attached 19-inch Goodyear tires, combined with the overwhelming presence of the V8 powertrain, create a striking appearance and communicate the GT40 concepts performance credentials.

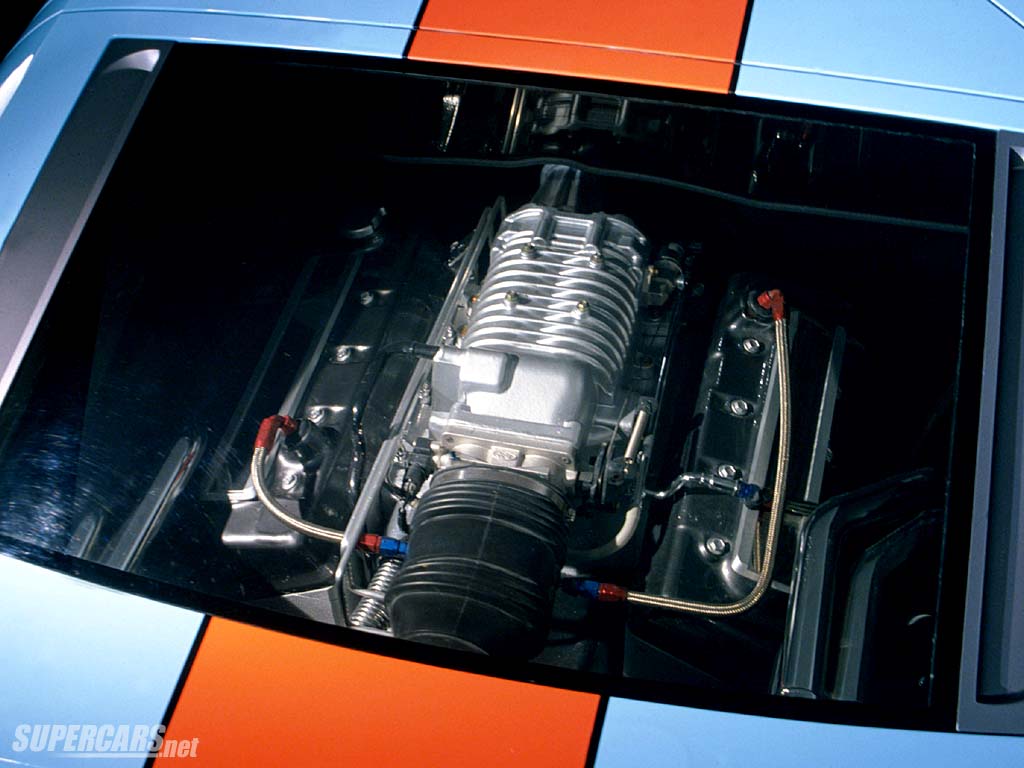

Engine

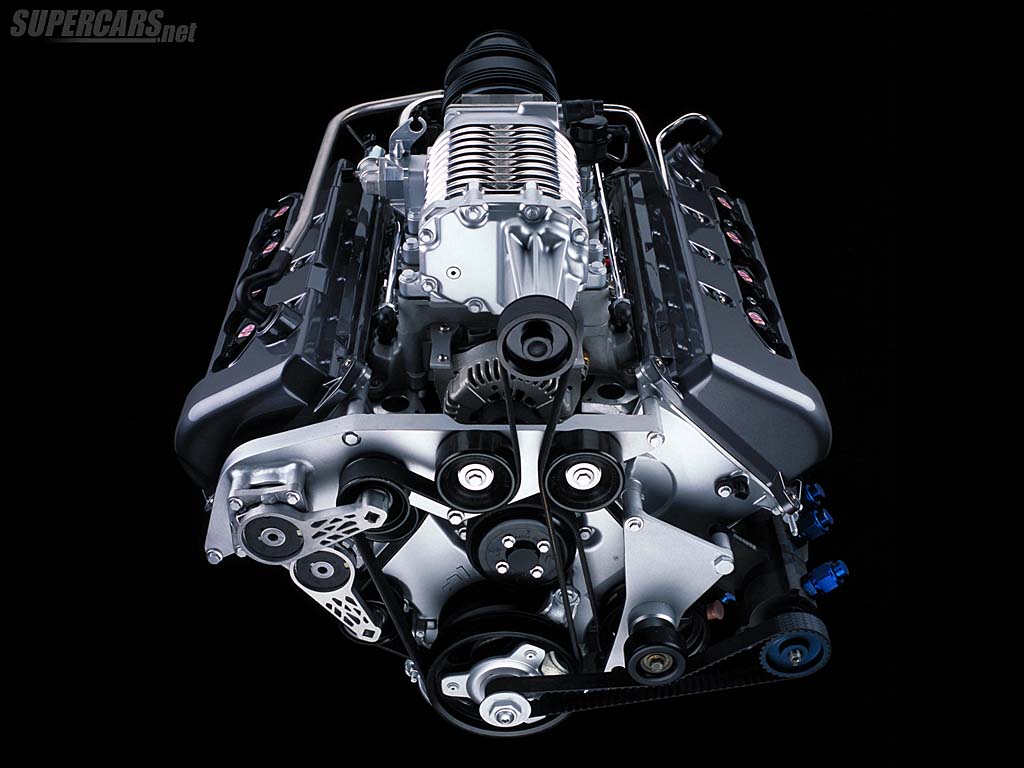

More than three decades ago, when the European competition was busy building complicated, high-strung V-12s, Ford proved that a simpler, more traditional V-8 approach could provide competitive power, a tremendous torque advantage, and the reliability needed for endurance racing.

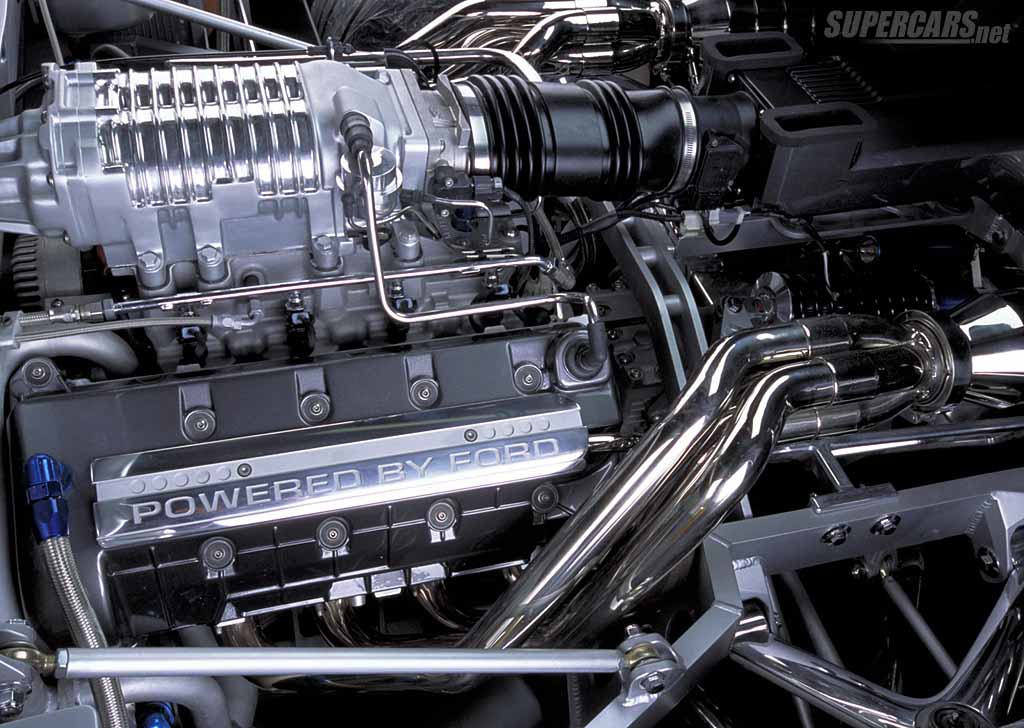

Today’s MOD 5.4-liter V-8 builds on that heritage. In this application, the largest V-8 in Ford’s modular engine family produces 500 horsepower at 5250 rpm and 500 foot-pounds of torque at 3250 rpm. Both figures are comparable to those of the 7-liter engine that won the 24 Hours of Le Mans in 1966 and 1967.

The all-aluminum MOD V-8 has been fitted with high-flow, four-valve cylinder heads and dual overhead camshafts. To bear the stresses necessary to produce 500 horsepower, Coletti used a forged steel crankshaft, shot-peened H-beam connecting rods from Manley, and forged aluminum pistons from Karl Schmidt Unisia. The engine uses a modified Roots-type supercharger from Eaton with an intercooled intake.

Behind the 9-inch heavy-duty McLeod clutch, the SVT team installed a special transaxle to accommodate the mid-engine layout. Sourced from RBT, the close-ratio six-speed uses internal components from transmission manufacturer ZF. It is fully synchronized and features an integral limited-slip differential.

Interior

The new GT40 is a left-hand-drive two-seater featuring leather-wrapped, custom Recaro bucket seats. Aluminum grommets that allow occupants more ventilation are embedded into the stitching. For easy access, the adjustable handle to control seat position is located on the front of the seat, rather than below.

The interior design incorporates the novel ventilated seats and instrument layout of the original car, with straightforward analog gauges and large tachometer. Modern versions of the original car’s toggle switches operate key systems.

Conclusion

The GT40 concept was created to foretell and test the future of exciting Ford cars to come. As with other Living Legends concepts, including the 1999 Thunderbird concept and Forty-Nine concept, the GT40 was engineered from the beginning for production feasibility. Ford’s SVT Engineering, which also created performance versions of the Focus, Mustang Cobra and F-Series Lightning, developed the chassis and powertrain. SVT Engineering worked closely with designers to ensure the concept would live up to its performance heritage.

2002 Ford GT40 Concept Gallery

In Detail

| submitted by | Richard Owen |

| built at | Detroit, Michigan, USA |

| engine | All Aluminum MOD V8 |

| position | Mid Longitudinal |

| aspiration | Supercharger w/Intercooler |

| valvetrain | DOHC, 4 Valves per Cyl |

| displacement | 5400 cc / 329.5 in³ |

| bore | 90.2 mm / 3.55 in |

| stroke | 105.8 mm / 4.17 in |

| compression | 8.5:1 |

| power | 372.9 kw / 500.1 bhp @ 5250 rpm |

| specific output | 92.61 bhp per litre |

| bhp/weight | bhp per tonne |

| torque | 677.91 nm / 500.0 ft lbs @ 3250 rpm |

| body / frame | Unstressed Composite Body over Aluminum Space Frame |

| front tires | 245/45R18 |

| rear tires | 285/45R19 |

| front brakes | Alcon Ceramic Cross-Drilled Discs w/6-Pot Calipers |

| f brake size | x 380 mm / x 15.0 in |

| rear brakes | Alcon Ceramic Cross-Drilled Discs w/6-Pot Calipers |

| r brake size | x 380 mm / x 15.0 in |

| front wheels | F 45.7 x 20.3 cm / 18.0 x 8.0 in |

| rear wheels | R 48.3 x 25.4 cm / 19.0 x 10.0 in |

| f suspension | Unequal Length Control Arms w/Rod Push-Bell Crank System, Spring |

| r suspension | Unequal Length Control Arms w/Rod Push-Bell Crank System, Spring |

| wheelbase | 2710 mm / 106.7 in |

| front track | 1636 mm / 64.4 in |

| rear track | 1650 mm / 65.0 in |

| length | 4613 mm / 181.6 in |

| width | 1950 mm / 76.8 in |

| height | 1106 mm / 43.5 in |

| transmission | RBT 6-speed Manual |

| gear ratios | 2.86:1, 2.06:1, 1.47:1, 1.18:1, 0.958:1, 0.740:1, :1 |

| final drive | 4.22:1 |