2004 Pininfarina Nido Concept

With the Nido project, Pininfarina has chosen to rethink the current methodology of the car design process, resulting in an innovative concept, which reexamines safety in small automobiles.

The Nido project dives into the concept of total design: coherent integration of all aspects of the design and engineering of the car. This concept was in fact conceived through an intense collaboration between design and engineering, two poles often opposed, with the singular goal of creating an attractive, small and safe vehicle. By focusing and redefining their respective approaches on a singular goal from day one, new innovative solutions were discovered in the overlap between the aesthetic and the technical view points.

Principle of the Nido Project

The Nido project has concentrated on the development and prototyping of new solutions involving both the structure and the design of a small two-seater car with the objective of increasing levels of safety for both the occupants and pedestrians.

The principle normally applied to protect occupants in the event of a head-on collision entails ensuring that sufficient space is maintained to accommodate the biometric parameters of the passengers, by using the programmed deformation of components to absorb impact energy. This is achieved in part through the deformation of the front of the vehicle, in part transferring the remaining loads to the rear of the vehicle (via floor panels, side members, doors and the structure as a whole) and in part with active retention systems (seatbelts and airbags).

Applying this principle in a compact vehicle poses many more difficulties than in a larger car, as there is very limited space to accommodate crumple zones. This leads to problems in the design of structural components that comply with increasingly strict legislation. While the structure will withstand a violent impact, the very rigidity of the chassis, together with the limited space available, means that a significant proportion of the energy is transferred to the occupants. As the dimensions of the front of the vehicle cannot be increased, it is necessary to find an alternative solution to reduce the forces of deceleration acting on the occupants to levels comparable with those of larger vehicles.

Rather than basing the safety characteristics of the car on its mass, as is the traditionally accepted method, Nido puts forward a new principle having a rigid cell, sled and energy absorbers.

image: http://www.supercars.net/graphics/2004_pininfarina_nido-7.gif

2. A shell for the occupants, accounting for approximately one third of the vehicle mass. This shell holds the driver and the passenger, together with the driving controls and instruments. This shell is actually a sled which can run horizontally along a central runner within the rigid cell.

3. The rigid cell and the sled are connected in normal conditions by a third element, consisting of two energy dissipating absorbers with controlled rigidity achieved by the combination of three honeycomb sections of different density.

In the event of a head-on collision, the vehicle absorbs part of the energy with the deformable front section of the chassis, constructed of two metal struts with internal plastic foam absorbers. These components are shaped as truncated cones in order to dissipate the energy over the cellular sheet metal firewall, which in turn transfers the energy along the central tunnel and the side members. The remaining energy, due to the mass of the dummies and the sled, shifts the sled itself forward and compresses the two honeycomb absorbers between the rigid cell and the dashboard of the sled shell, resulting in the gradual and controlled deceleration of the dummies.

The insertion of honeycomb absorber elements between the rigid cell and the sled shell means that, in a collision, the deceleration curve for the sled is lower than the curve for the rigid cell. Additional, smaller absorber elements may also be fitted between the rear of the sled and the rigid cell, to provide occupant protection in the event of a rear-on collision. This principle, applied here in a small, rear-engined two-seater city car may also be used in a mid-engined two-seater sports car.

The concept developed by the Nido project also includes the use of suitably sized transverse structures in the sled near the dash and at the base of the seats, which transfer lateral impact energy from one side of the car to the other. As a consequence, the doors rest on these transverse structures, an arrangement which also prevents door intrusion.

During the Nido project, a strong cooperative relationship between the different company divisions involved was established, and Pininfarina’s experience in virtual product development was put to full use, employing computer simulation for static and dynamic analyses. The simulations showed that thanks to the mobile sled system, the deceleration sustained by the occupants during a collision is low enough to render the use of airbags unnecessary in certain cases, meaning that the way in which they are currently used may be reconsidered.

Prototype Highlights

The overall architecture of the car was also chosen for functionality: the single-box shape allows more room for the motion of the sled shell and conveys an impression of a protective ‘nest’ (nido in Italian) surrounding the occupants. The sled consists of a shell of structural plastic reinforced by a sub-frame in stainless steel tubing to help keep the overall weight of the system as low as possible.

A new concept of chassis construction has also been developed, replacing the traditional floor tray, tunnel and firewall configurations with a structure in cellular sheet metal. The advantages of this technology lie in its improved energy absorption capacity in collisions and excellent torsional stiffness. Cellular sheet metal technology consists of a sandwich made up of four or more thin layers: flat sheets are used for outside sections, whereas for internal parts, two or more ribbed sheets were assembled together with their respective corrugations opposed.

The front moulding is completely covered with a cushion of energy absorbing material to present safer surfaces in the event of collision with a pedestrian, and thus minimise injury; it houses, among other elements, the windscreen wiper and windscreen washer fluid filler cap. To reduce head injuries in the event of a collision with a pedestrian, the windscreen pillar is also fitted with a collapsible covering consisting of an external plastic section to fit in with the rest of the bodywork and an internal energy-absorbing section made of the same foam used for the cushion.

The headlights are mounted high to increase the deformable area presented during collision with a pedestrian. In addition to an indicator light, the wing mirror incorporates a white reflector to ensure visibility at night when the vehicle is parked.

The low waistline, very wide windscreen and transparent roof ensure excellent visibility.

Inside

The interior trim and fittings were not simply designed for style, but have been developed in consideration of the impact dynamics of the occupants during an accident. The doors are fitted with rhomboid aluminium alloy hinges and are oversized in comparison with average comparable components on other cars to facilitate the exit of occupants after an accident. The inner door panel has been designed so that there are no hazardous protuberances during a collision.

A number of parts inside the passenger compartment are made from soft materials. The door handles, for example, also function as emergency door releases. They are fabric straps, which can be used to open the door from whichever position the occupant is in after an accident. The stowage compartments are fabric pockets.

The dash assembly serves a dual role: it houses the instruments and is an integral part of the sled shell, acting to compress the honeycomb absorber during a collision. Furthermore, the dash itself also performs an energy-absorbing role, as its internal components (heater, air pipes) have been designed to contribute to dissipating energy in a collision. The underdoor side member is larger than usual as it incorporates a number of ‘crashbox’ elements which absorb energy in a lateral collision.

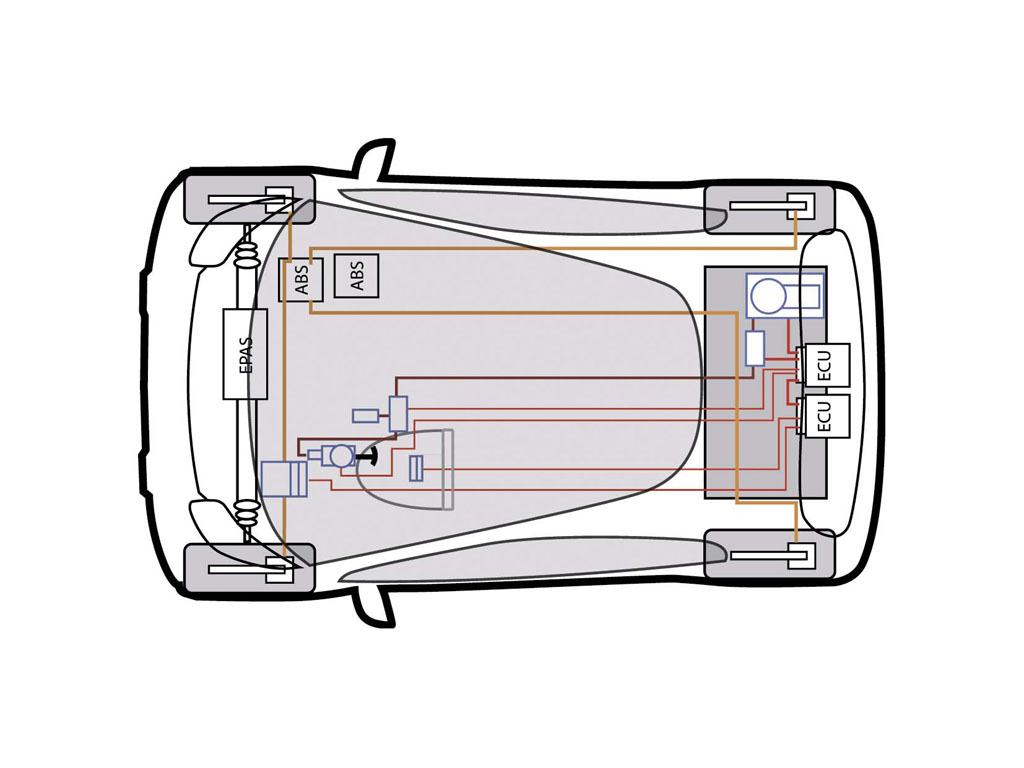

To maximise the effectiveness of the Nido principle, the space normally taken up by the steering column and traditional pedal box has been freed up by the use of a ‘steer and brake by wire’ system, which means that these components no longer intrude into the passenger compartment and also allow the use of a spokeless steering wheel. This last feature optimises instrument visibility, thus further contributing to safety.

A veltex trim has been applied on the dash and tunnel, so that any loose object (mobile phone, MP3 player, satellite navigator etc) can be fixed by simply applying a Velcro type strip on the object itself. On the one hand, this contributes to cutting the basic cost of the car, by balancing off the greater expense of the safety features with simpler internal trim, and on the other, it means that the interior of the car can be personalised according to individual tastes and requisites.

The Future

The last stage in the project will consist in industrial feasibility studies for a hypothetical production of 100-120 cars per day for a total of 20,000 units over 5 years. Pininfarina has applied for patents for the innovative safety features developed as part of the Nido project.

Story by Pininfarina S.p.A., edited by Supercars.net

In Detail

| submitted by | Richard Owen |

| position | Rear Engine |

| body / frame | Composite Body |

| driven wheels | RWD |

| front tires | 175/50 16 |

| rear tires | 205/45 16 |

| f brake size | mm / in |

| r brake size | mm / in |

| wheelbase | 2068 mm / 81.4 in |

| length | 2890 mm / 113.8 in |

| width | 1674 mm / 65.9 in |

| height | 1534 mm / 60.4 in |

| transmission | Automatic |

| gear ratios | With the Nido project, Pininfarina has chosen to rethink the cur:1, :1 |