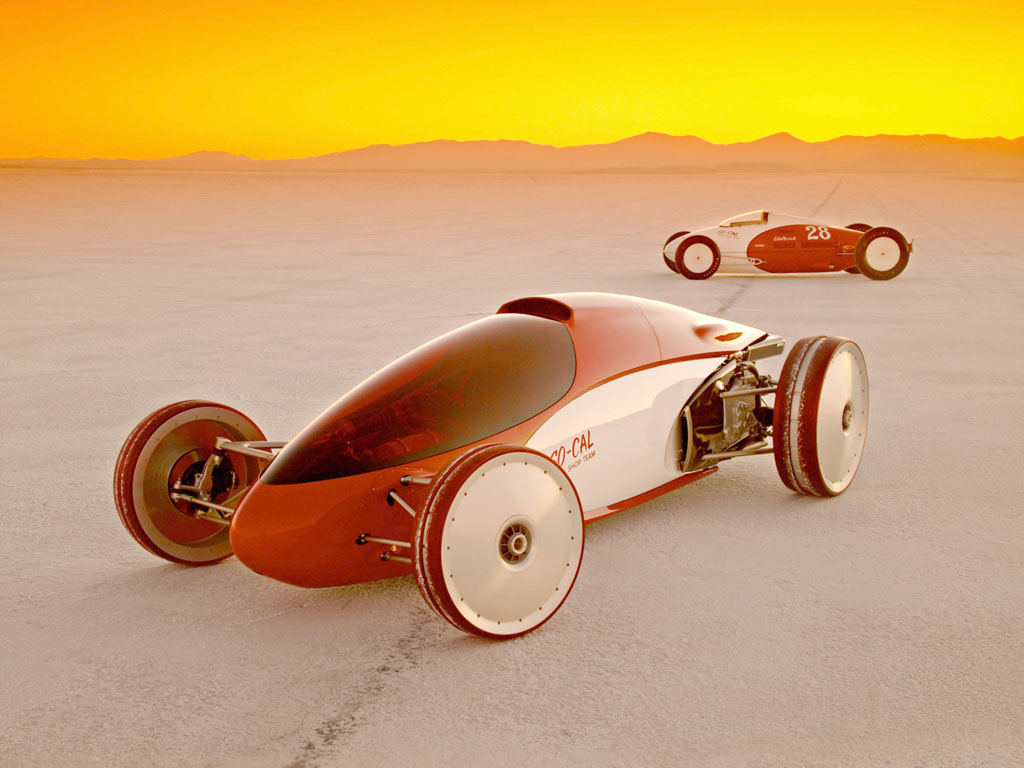

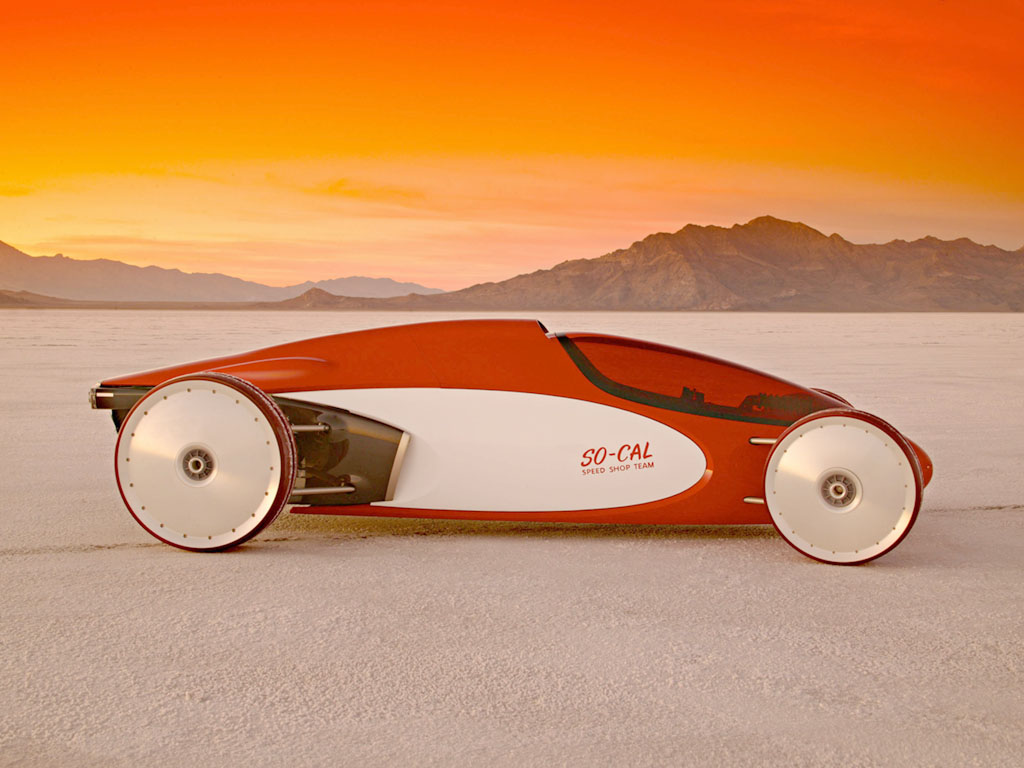

2003 So-Cal Lakester

No vehicle expresses the ingenuity and unbridled innovation of hot rodding more forcefully than the belly tank lakester. Conceived by hot rodders in the late ’40s to minimize aerodynamic drag and fashioned from war surplus auxiliary fuel tanks formerly mounted on the bellies of military aircraft, these open-wheeled inventions set records on the dry lakebeds of Southern California and on the glistening white salt of Bonneville.

One of the most famous of the breed was the So-Cal Speed Shop belly tank. Featured on the cover of the January 1949 issue of Hot Rod magazine, this streamlined projectile still appears as purposeful as a Stealth fighter. Fabricated from found materials and built by hand on a nonexistent budget, the belly tank was avant garde in its time. Now 55 years later, the soul of the original So-Cal lakester has been reborn.

GM Performance Division conceived a belly tank lakester for the 21st century to demonstrate the versatility of the Ecotec engine. Instead of the original’s war surplus components, the reinvented lakester was constructed from high-tech materials using advanced digital design techniques. In place of a rudimentary flathead V-8 is a sophisticated supercharged Ecotec engine. But despite the vast differences in materials and technology that distinguish the two vehicles, the modern version remains true to the spirit of the famous So-Cal belly tank lakester.

The reborn belly tank has many parents: Mark Reuss, executive director of GM Performance Division; Frank Saucedo, director of design for the GM Advanced Studio in North Hollywood, Calif.; David Bolognino, GM concept vehicle manager; Alex Xydias, founder of the So-Cal Speed Shop and co-owner of the original car; and dozens of designers, fabricators, gearheads and hot rodders who eagerly enlisted in the cause to bring back the belly tank.

Saucedo and the staff of GM’s West Coast design center employed many of the tools and techniques that they use to create cutting-edge concept cars and eye-catching GM production vehicles in car-conscious California. In the course of this project, the GM Advanced Studio redefined the traditional lakester. The sculptured skin is formed from lightweight composite material, with a silhouette that follows the curve of the original and a three-dimensional scallop that echoes the original So-Cal Speed Shop paint scheme. The list of materials used to form the body reads like the manifest for a B2 bomber, including carbon fiber, Kevlar and Lexan.

The exposed Ecotec engine is a radical departure from the fully enclosed streamliners of the past. One of the goals of this engineering exercise was to showcase the versatility of the Ecotec engine – and to inspire enthusiasts to think outside the box about GM’s premier four-cylinder powertrain. The supercharged 2.0-liter Ecotec engine is mounted transversely, just as it is in the production Saturn ION Red Line, with a production transmission driving the rear wheels.

The roots of the So-Cal belly tank can be traced directly to a war surplus store in Glendale, Calif. Among the legions of hot rodders who served in the Armed Forces during World War II, Bill Burke was the first to recognize that the teardrop-shaped auxiliary gas tanks that were used to extend the range of military aircraft offered an ideal shell for a land speed racer. When he returned to civilian life, Burke constructed his first lakester from a 168-gallon P51 Mustang belly tank, but that design proved too small to accommodate an engine and driver. The twin 305-gallon tanks mounted on P38 fighters soon became the tanks of choice among aspiring record setters.

In the world of hot rodding, the leap from war surplus gas tanks to digitally designed concept cars is simply another expression of the abiding passion for innovative automobiles.

Story by GM, Edited by SC.net

In Detail

| type | Racing Car |

| built at | USA |

| engine | Ecotec SC Inline-4 w/Supercharger |

| position | Transverse |

| valvetrain | DOHC, 4 Valves per Cyl |

| fuel feed | Sequential Fuel Injection |

| displacement | 1998 cc / 121.9 in³ |

| bore | 86 mm / 3.39 in |

| stroke | 86 mm / 3.39 in |

| compression | 9.5:1 |

| power | 149.1 kw / 200 bhp @ 6200 rpm |

| specific output | 100.1 bhp per litre |

| bhp/weight | 245.1 bhp per tonne |

| torque | 271.16 nm / 200 ft lbs @ 4400 rpm |

| redline | 6500 |

| body / frame | Composite Body over Steel Tube Frame |

| driven wheels | RWD |

| front brakes | Wilwood Discs w/4-Piston Calipers |

| rear brakes | Wilwood Discs w/4-Piston Calipers |

| front wheels | F 66.0 x 6.4 cm / 26.0 x 2.5 in |

| rear wheels | R 78.7 x 8.9 cm / 31 x 3.5 in |

| curb weight | 816 kg / 1800 lbs |

| wheelbase | 2667 mm / 105.0 in |

| front track | 1524 mm / 60 in |

| rear track | 1524 mm / 60 in |

| length | 4064 mm / 160.0 in |

| width | 889 mm / 35 in |

| height | 1041 mm / 41.0 in |

| transmission | Hydra-Matic 4T40-E 4-Speed Auto |