BMW i8 (2014 – Present): Profile, Specifications, Reviews & Buyer Guide

Introduction

With all the new technologies that seem to be bursting through the pipeline these days, it has become hard to remember the time when the BMW i8 was first unveiled to the public. Released during what feels like the olden days now, the 2014 BMW i8 revolutionized the automotive landscape by pioneering what is recognized to be the first high-performance hybrid sports car.

Well ahead of its time, its powertrain technology was the result of BMW’s visionary approach to a rapidly shifting narrative towards a future focused on sustainability. The eventual overthrowing of the combustion engine would be at the forefront of this movement, with EVs taking their place. The BMW i8 would be the earliest creation in this image.

The BMW i8 provides more of a transitional approach to this, than a radical one – being a plug-in hybrid as opposed to fully-electric – but would nevertheless be disrupting the status quo. Since its 2014 release, we are still currently in the same production run based on the initial platform.

While the original car was relatively trailblazing for its time, BMW hasn’t made a whole lot of changes to the i8 since its 2014 release. There have been few noteworthy upgrades, if any, unless the optional Laserlight headlamps introduced in 2016 are your thing.

The 2019 model year has seen the most significant changes, where the the BMW i8 is now also available as a soft-top roadster in addition to the 2+2 coupe. The powertrain has also been revised to produce an additional 12-horsepower while also increasing overall range by about 3 miles.

The latest BMW software – iDrive 6.0 – now runs via the car’s infotainment system, while minor changes to the dampers and anti-roll bars are intended to improve handling performance and driving feel.

Should you buy one? What are the specifications? What do the reviews say?

Supercars.Net has put together this page as a resource to help answer all of these questions, and more.

Our Take: Should You Buy a BMW i8?

The BMW i8 is certainly the type of car that makes a statement. At the forefront of this are its revolutionary hybrid drivetrain, and a sharp amalgamation of futuristic and exotic design elements.

However, with today’s offerings it has become an increasingly hard sell as far as the i8 is concerned – especially when taking into consideration performance figures. While its purely petrol-powered competitors (based on price) – such as the Audi R8 and BMW M4 – could arguably be waved off as incomparable, new players to the green-scene include the much more utilitarian Porsche Taycan and the accessibly-priced Tesla Model 3, while the old-rival Tesla Model S has seen continuous improvements over time.

In the short-term, many of the mainstream automakers such as Audi, Aston Martin, Kia and Mercedes are looking to enter the game with their own lineup of EVs, which will only further flood the market with more options – good for the consumer, not so great for the i8.

Bottom line: The BMW i8 is still a very cool, head-turner of an automobile, and speaks strongly for the EV movement thanks to its status as a pioneer and revolutionary. The used market is probably the best path to procuring one; a patient approach is likely to pay dividends, depreciation is set to accelerate as the market becomes saturated with eco-friendly vehicles.

[row][column size='1/2']

Reasons To Buy The BMW i8

- Good performance for a hybrid (369-horsepower for 2019 model year)

- Excellent fuel economy/range for a sports car (27 mpg combined)

- Futuristic design is bound to turn heads, great way to make an eco-friendly statement

- Has collector-appeal due to its history, exclusivity

- Available as a roadster for 2019 model year

[/column]

[column size='1/2']

Reasons Not To Buy The BMW i8

- Performance lagging behind in-class and price-range competitors

- Sparingly appointed interior doesn’t match its asking price

- Impractical and poor visibility, even by sports car standards

- Buying brand new will cost more than double of what a gently used 2016 is going for

- iDrive software feels dated compared to other current infotainment offerings

[/column]

[/row]

Notable Model-Year Changes

Production Run

The BMW i8 has been produced since 2014 and is still on its current production run. 2019 is the most current model year.

[row][column size='1/2']

2016 Model Year

- Optional BMW Laserlight headlamps introduced

[/column]

[column size='1/2']

2019 Model Year

- Revised drivetrain + 12-horsepower and +3 miles EV range

- Recalibrated dampers and changes to improve handling and feel

- Available in roadster version, with soft top

[/column]

[/row]

2019 BMW i8 Reviews

Below are snippets of reviews from some of the most trusted sources when it comes to automotive journalism. These reviews speak specifically to the 2019 model year, but will encompass some commentary and comparisons to the previous years, and the production run as a whole.

Top Gear – 9/10: “This is the future, supercar buyers. If this is how it’s to be, bring it on…. There’s nothing like the i8. Its bewildering complexity stems from the need to build a new-age sustainable sports car.” Link to full article

The Car Connection – 6.8/10: “The 2019 BMW i8 is a head-turner for its looks, which hides its plug-in powertrain. That’s good or bad, depending on your priorities… The i8’s performance is impressive considering its efficient powertrain—not its relatively high price.” Link to full article

Autocar – 4.5/10: “BMW would have you believe that the new i8 is the sports car of the future – and it’s a believable claim of a car that is daring, exotic and state of the art in just about every way you might judge it…. A prodigy. Good in places where the others are brilliant; brilliant where its rivals are nowhere.” Link to full article

Motor1.com – 6.1/10: “The BMW i8 pioneered its class, but not even the new Roadster slows the aging process… Sure, the i8 doesn’t return Prius-type numbers (which docks its overall score on our scale), but it strikes the ideal balance between sporty and efficient for the class. And it’s plug-in ability makes it even more appealing.” Link to full article

2019 BMW i8 Competition

If you’re looking at purchasing a BMW i8, you may also want to cross-shop these alternatives which fall into the same price-range, class, or a combination of the two.

Acura NSX / Taycan Turbo S / Audi R8 / Tesla Model S / Aston Vantage / Lexus LC500h

2019 BMW i8 Specifications

Engine |

|

| Type (Electric) | AC Synchronous Electric Motor with integrated power electronics, charger and generator mode for recuperation |

| EDrive Motor Horsepower | 141 hp @ 4,300 rpm |

| EDrive Motor Torque | 184 hp @ 0-4,100 rpm |

| Type (Petrol) | 1.5L TwinPower Turbo 3-cylinder |

| Engine Horsepower | 228 hp @ 5,800-6,000 rpm |

| Engine Torque | 236 lb-ft @ 3,700 rpm |

| Combined HP/TQ | 369 hp / 420 lb-ft |

| Battery Type | 11.6 kWh lithium-ion / 33 ah |

Transmission |

|

| Type (Electric) | AC Synchronous Electric Motor with integrated power electronics, charger and generator mode for recuperation |

| Automatic Gear Ratios | 11.30, 5.85 |

| Type (Petrol) | 6-speed automatic transmission |

| Automatic Gear Ratios | 4.46, 2.51, 1.56, 1.14, 0.85, 0.67 |

| Final Drive Ratio | 3.68 |

| Coefficient Drag | 0.27 (0.28 for roadster) |

| Drive Type | All-wheel drive |

Performance, Consumption, Wheels & Tires |

|

| 0-60 mph | 4.2 seconds (4.4 seconds for roadster) |

| Top Speed | 155 mph |

| EV Range | 23 miles |

| Total Range | 330 miles |

| MPGe Combined | 69 MPGe |

| Fuel Tank Capacity | 11.1 gallons |

| Charging Time (0-100%) | 3 hours |

| Wheel Dimensions | 20” x 7.5” front, 20” x 8.5” rear |

| Tire Dimensions | 215/45 front, 245/40 rear |

Exterior Dimensions |

|

| Doors / Seats | 2 / 4 (2 / 2 for roadster) |

| Length / Width / Height | 184.9” / 76.5” / 50.8” |

| Ground Clearance | 4.6” |

| Curb Weight | 3,501 lbs (3,671 lbs for roadster) |

| Weight Distribution | 48.8% front, 51.2% rear (48.5%, 51.5% for roadster) |

Interior Dimensions |

|

| Headroom | 38.7” |

| Legroom | 43.1” front, 28.2” rear (rear n/a for roadster) |

| Shoulder Room | 56.7” front, 49.6” rear (rear n/a for roadster) |

| Cargo Capacity | 4.7 cu.ft. (2.3 cu.ft for roadster) |

Price |

|

| Base Price – Coupe | $147,500 USD |

| Base Price – Roadster | $163,300 USD |

Images & Video Review Gallery

See full 2014 BMW i8 Gallery here

Video Reviews

Other Useful Resources

Bimmerfest Forums / BMW i Forums

Legacy Content

The BMW i brand is synonymous with visionary mobility concepts and a new definition of premium quality that is strongly focused on sustainability. Following the world debut of the first production model, the BMW i3, the BMW Group’s next step will be to extend this revolutionary answer to the future challenges facing personal mobility to the sports car segment. At a driving event at the BMW Group’s Miramas test track in France, the BMW ibrand is now presenting a prototype of its second production vehicle, the BMW i8. This plug-in hybrid model is the most progressive sports car of our time, extending the basic BMW i philosophy of sustainability to a new vehicle segment.

The BMW i8 embodies hallmark BMW driving pleasure in a revolutionary and mould-breaking form. This is reflected in a highly emotive design, dynamic sports car performance, and fuel consumption and emissions figures worthyof a small car. Pairing an exceptionally lightweight, aerodynamically optimised body with cutting-edge BMW eDrive technology, a compact, highly turbocharged 1.5-litre BMW TwinPower Turbo petrol engine and intelligent energy management, the BMW i8 marks the next stage in the evolution of the Efficient Dynamics strategy. Its revolutionary approach achieves an unprecedented balance between performance and fuel consumption. Thanks to its carbon-fibre-reinforced plastic (CFRP) passenger cell, the BMW i8 sets new standards for a plug-in hybrid vehicle in terms of low weight. It can operate solely on electric power, which means no tailpipe emissions, and offers the dynamic performance of a sports car, with an expected 0 –100 km/h (62 mph) sprint time of 4.5 seconds.

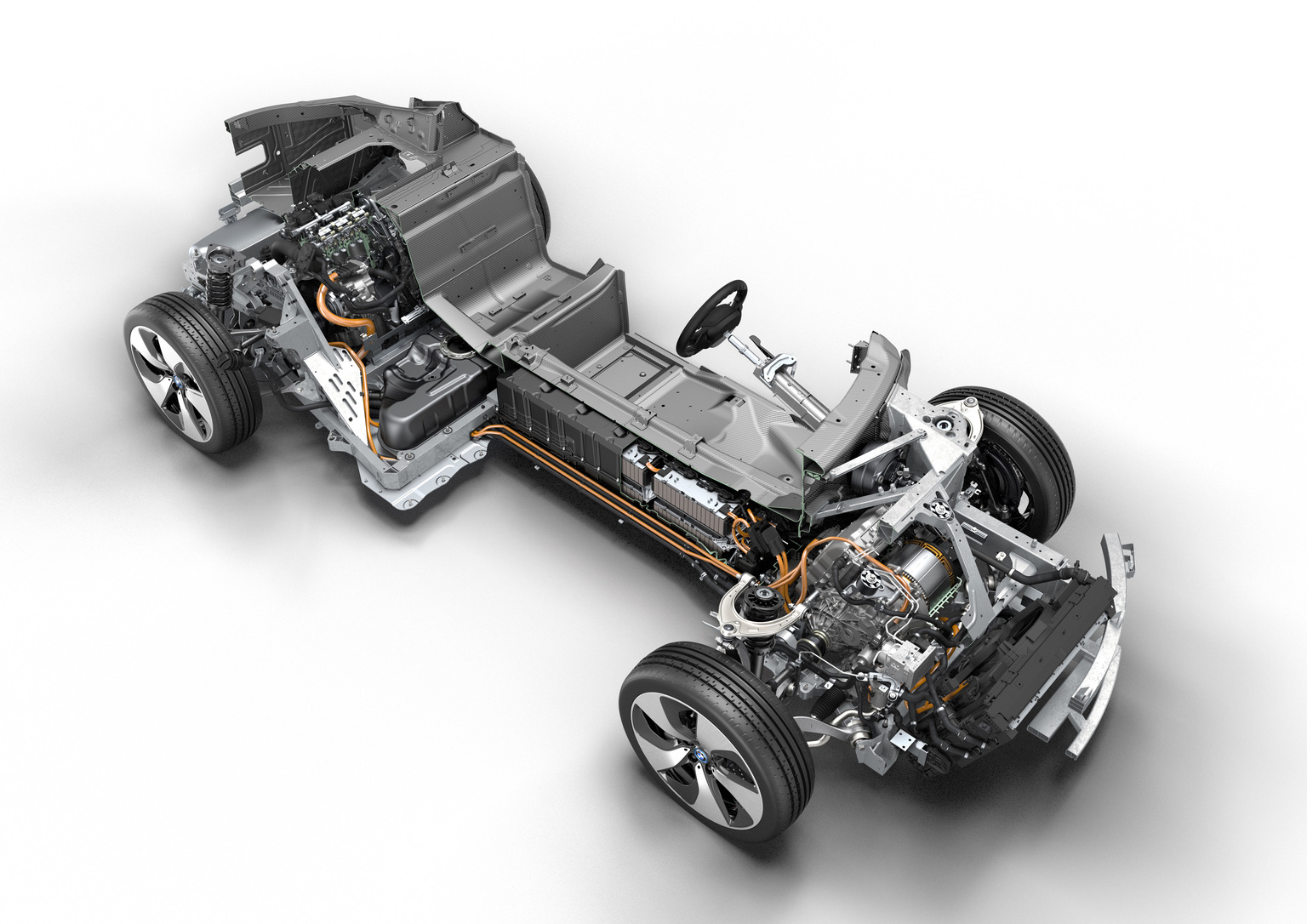

The BMW i8 was designed from the outset as a plug-in hybrid sports car, with the emphasis on agile performance and outstanding efficiency. Its characteristicBMW i LifeDrive architecture provides the best possible basis for lightweightdesign. Its main components are the aluminium Drive module, which incorporatesthe internal combustion engine and electric motor, the battery, the power electronics and the chassis components, along with structural and crash functions, and the Life module, which essentially comprises the 2+2-seater CFRP passenger cell. This architecture also gives the BMW i8 a very low centre of gravity and a near-perfect 50:50 axle load ratio, both of whichincrease its agility.

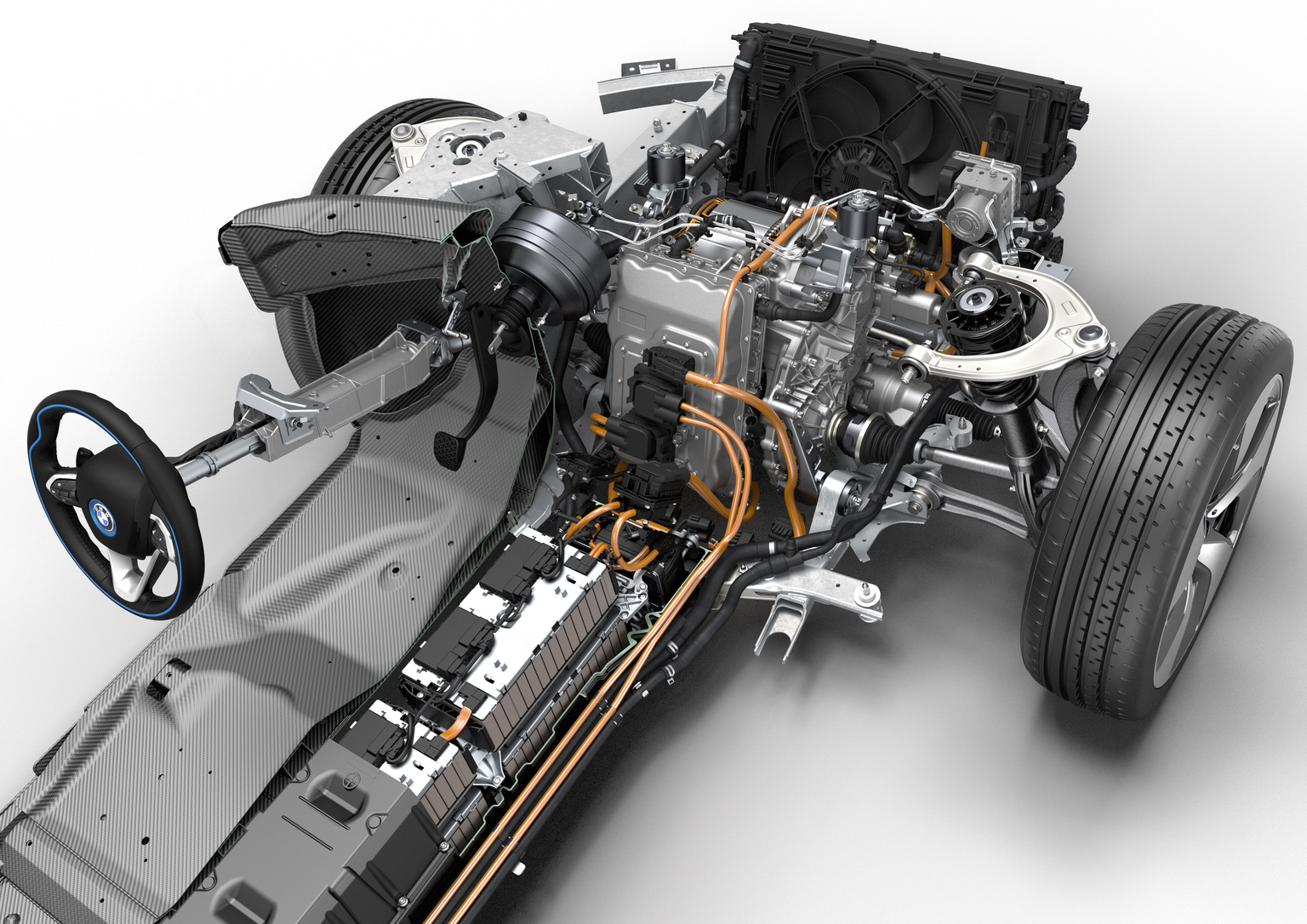

The BMW i8’s plug-in hybrid system is specific to this model. Developed and produced by the BMW Group, it marks the next step in the evolution of the Efficient Dynamics programme. A compact three-cylinder petrol engine with BMW TwinPower Turbo technology is combined with an electric drive system and a lithium-ion battery which can be recharged at a standard household power socket. The 170 kW/231 hp petrol engine sends its power to the rear wheels, while the 96 kW/131 hp electric motor powers the front wheels. This configuration offers all-electric driving capability with a range of up to 35 kilometres (approx. 22 miles) and a top speed of 120 km/h (approx. 75 mph). With both drive systems engaged, it also offers road-hugging allwheel-drive performance with powerful acceleration and dynamic torque vectoring during sporty cornering. The more powerful of the two powerplants drives the rear wheels. The hybrid system supplements this with power from the electric motor to deliver typical BMW driving pleasure combined with groundbreaking efficiency. Calculated using the EU test cycle for plug-in hybrid vehicles, the average fuel consumption of the BMW i8 at model launch will be less than 2.5 litres/100 km (over 113 mpg) with CO2emissions of less than 59 grams per kilometre

Efficient Dynamics

It is now more than a decade since the BMW Group launched its Efficient Dynamics vehicle development strategy, whose aim is to significantly improve both the performance and the efficiency of new BMW Group models. Efficient Dynamics combines evolutionary advances in existing technologies with the development of new and revolutionary drive concepts. Efficient Dynamicssolutions include efficient lightweight design and aerodynamic concepts,high-performance drive systems based on TwinPower Turbo technology and BMW eDrive, and intelligent management of all energy flows within the vehicle. The new, revolutionary technology now being introduced on models of the BMW i brand will subsequently find its way into the vehicles of the BMW Group’s core brands.

BMW i is also setting benchmarks in the quest for zero CO2emissions in urban driving. The research and development work carried out since 2007 as part of project i has laid the foundations for revolutionary mobility solutions strongly influenced by environmental, economic and social change around the world. The BMW Group is pursuing an integrated approach, as embodied in the new BMW i brand, which aims to achieve the necessary balance between individual needs and the global mobility requirements of the future. TheBMW i focus is squarely on all-electric and plug-in hybrid mobility. Groundbreaking design, intelligent lightweight engineering, typical BMW driving pleasure coupled with zero emissions, intelligent energy management and resource- and energy-saving production processes are all combined intoan innovative premium-quality package.

LifeDrive architecture

The LifeDrive architecture specially developed for BMW i vehicles offers the ideal platform for turning the tide of spiralling weight while at the same time achieving distinctive styling exclusive to BMW i. With a length of 4,689 mm, a width of 1,942 mm and a height of 1,293 mm, the BMW i8 has the proportionsof a typical sports car. Its dynamic personality is also stressed by a long bonnet,conspicuous aerodynamic features, an elongated roofline, short overhangs and a long wheelbase of 2,800 mm. Characteristic BMW i form language wraps up this groundbreaking combination of sporty performance and efficiency in a charismatic 2+2-seater design.

The BMW i8 combines a drag coefficient (Cd value) of 0.26 with outstanding aerodynamic balance. The finely honed air flow around all parts of the vehicle body makes for an excellent lift/drag ratio, resulting in superb driving dynamics and stability.

Intelligent lightweight design

With its combination of the aluminium Drive module and the CFRP passenger cell (Life module), the BMW i8 is also an excellent example of intelligent lightweight design – one of the guiding principles of the Efficient Dynamics strategy. Use of the lightweight high-tech material CFRP, which also offers excellent crash performance, brings weight savings of 50 per cent over steel and around 30 per cent over aluminium, with equivalent or improved strength. These savings offset the weight penalty of the electric motor and the high voltage battery, giving the BMW i8 an unladen weight of less than 1,490 kilograms. The LifeDrive architecture also brings benefits in terms of weight distribution. The battery pack is situated low down in the middle of the vehicle, resulting in a low and central centre of gravity, which improves safety. No other current model of a BMW Group brand has such a low centre of gravity.

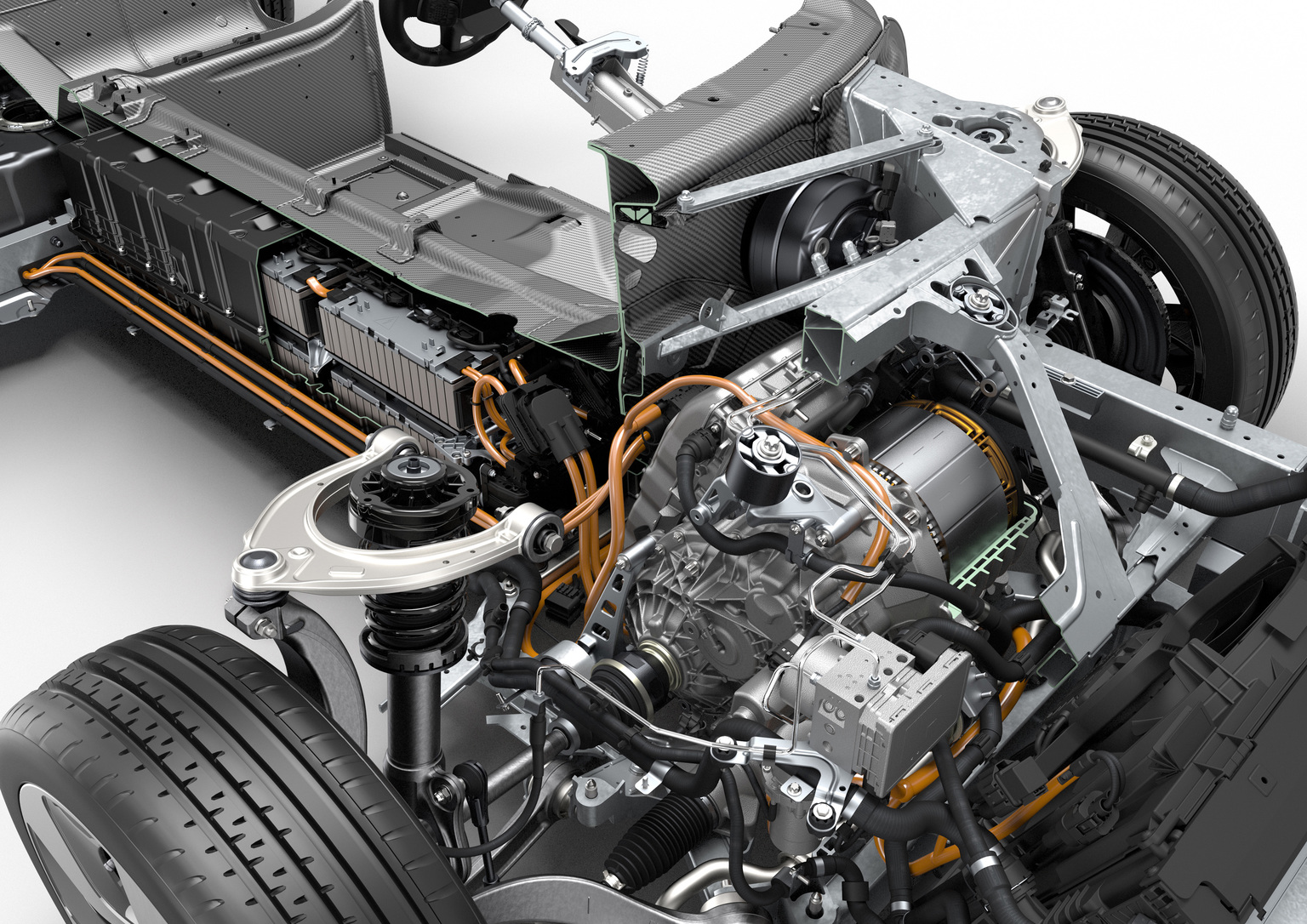

The front-rear axle load distribution maximises agility with a near-perfect 50:50 axle load ratio. The compact electric motor, together with the transmission and power electronics, are situated in close proximity to the electrically powered front axle. The highly turbocharged petrol engine, which is located together with its transmission in the rear of the BMW i8, likewise sends its power to the road via the shortest possible route, i.e. through the rear wheels. As a finishing touch to this excellent weight distribution, the lithium-ion battery pack is centrally located in the vehicle, slightly forward of the mid-point. In terms of crash safety, this is an ideal location for the battery, which is integrated in an aluminium housing.

The doors comprise a CFRP inner structure and an aluminium outer skin. This reduces the weight of the door by 50 per cent compared with a conventional design. The high-quality, naturally tanned leather of the seats highlights the “next premium”, sustainable philosophy of BMW i.

The magnesium instrument panel support saves weight on two fronts – firstly through intelligent design, leading to around 30 per cent weight savings compared, for example, with the BMW 6 Series. In addition, the high structuralrigidity provides a strengthening effect which allows the number of components to be reduced, thereby lowering weight by a further 10 per cent. Innovative foam plastic technology used in the air conditioning ducts brings 60 per cent weight savings over conventional components, while also improving acoustics thanks to its sound-absorbing properties.

The fact that the power electronics and electric motor are directly connected reduces the amount of wiring required, while partial use of aluminium wiringbrings further weight reductions. Lightweight design is also a feature of the BMW i8’s chassis systems – including the wheels, where the standard-fitted 20-inch forged aluminium wheels combine aerodynamic design with weight savings. The rigorous application of the lightweight design strategy even extends to aluminium screws and bolts, which are around 45 per cent lighter than corresponding steel components, with the same strength and functionality.

The BMW i8 is also the world’s first volume-produced vehicle to be equipped with chemically hardened glass. This innovative technology, to date used mainly in Smartphone manufacturing, results in very high strength. Thepartition between the passenger compartment and boot of the BMW i8 consists of two layers of chemically hardened glass, each of which is just 0.7 millimetres thick, with acoustic sheeting sandwiched between. In addition to excellent acoustic properties, a further advantage of this solution is weight savings of around 50 per cent compared with conventional laminated glass.

BMW TwinPower Turbo

The plug-in hybrid system of the BMW i8, which comprises a BMW TwinPower Turbo engine combined with BMW eDrive technology,offers the best of both worlds: excellent potential for improved efficiency and exciting, sporty driving characteristics. The BMW Group has developed not only the internal combustion engine and electric motor in-house but also the power electronics and the battery. This ensures that all these components offer high product and quality standards, based on the outstanding capabilities of the BMW Group in the field of powertrain research and development.

The revolutionary character of the BMW i8 is emphasised by a further innovation: the use of a new internal combustion engine which is making its debut in this model. The BMW i8 is the first BMW production model to be powered by a three-cylinder petrol engine. This highly turbocharged unit is equipped with latest-generation BMW TwinPower Turbo technology. It isexceptionally compact and develops maximum power of 170 kW/231 hp. The resulting specific output of 113 kW/154 hp per litre of displacement is on a par with high-performance sports car engines and is the highest of any engine produced by the BMW Group.

The new three-cylinder engine derives its typical characteristics from the BMW six-cylinder in-line engines, to which it is closely related and which are noted for their eager power delivery, revving ability and refinement. The three cylinder’s BMW TwinPower Turbo technology comprises a high-performance turbocharging system and direct petrol injection with high-precision injectors positioned between the valves, along with VALVETRONIC throttle-less load control, which improves efficiency and response thanks to seamlessly variable valve lift control. Like a six-cylinder engine, the three-cylinder unit is free of first and second order inertial forces. The low roll torque, a typical feature of a three-cylinder design, is further reduced by a balancer shaft, while a multi-stage damper integrated in the automatic transmission ensures very smooth and refined running at low rpm. BMW TwinPower Turbo technology and low internal friction improve both fuel consumption and torque characteristics. Accelerator response is sharp and the three-cylinder unit quickly reaches its maximum torque of 320 Newton metres.

The BMW i8’s second power source is a hybrid synchronous electric motor specially developed and produced by the BMW Group for BMW i. The electric motor develops maximum power of 96 kW/131 hp and produces its maximum torque of around 250 Newton metres from standstill. Typical of an electric motor, responsive power is instantly available when starting and this continues into the higher load ranges. The linear power delivery, which extends right up to the high end of the rpm range, is down to a special motor design principle exclusive to BMW i. BMW eDrive technology refines and improves on the principle of the permanently excited synchronous motor via a special arrangement and size of the torque-producing components. This results in a self-magnetising effect normally confined to reluctance motors. This additional excitation ensures that the electromechanical field generated when current is applied remains stable even at high rpm.

As well as providing a power boost to assist the petrol engine during acceleration, the electric motor can also power the vehicle by itself. Top speed is then 120 km/h (approx. 75 mph). The BMW i8 has a maximum driving range in this emission-free, virtually soundless, all-electric mode of up to 35 kilometres (approx. 22 miles). The motor derives its energy from the lithium-ion battery which is centrally mounted underneath the floor of the vehicle. The model-specific version of the high-voltage battery was developed and produced by the BMW Group. It has a liquid cooling system and can be recharged at a conventional household power socket, at a BMW i Wallbox or at a public charging station. A full recharge takes less than three hours at a household power socket and less than two hours at a BMW i Wallbox.

The BMW i8’s vehicle concept and powertrain control system mark it out as a progressive, revolutionary sports car. The BMW i8 always achieves the optimal balance between performance and efficiency, whatever the driving situation. When power demands allow, the high-voltage battery is recharged by the electric motor. The high-voltage starter-generator, responsible for starting the engine, can also be used as a generator to charge the battery, the necessary power being provided by the BMW TwinPower Turbo engine. The battery can also be recharged via the electric motor during overrun. These various processes help to prevent depletion of the BMW i8’s battery in order to maintain the electric drive power. The all-electric driving range is sufficient to cover most urban driving requirements. Out of town, the BMW i8 offers impressively sporty performance which is also very efficient thanks to the power-boosting support for the petrol engine from the electric motor. With such versatility, the BMW i8 belongs to a new generation of sports cars which unites exciting performance with cutting-edge efficiency – to enhance both driving pleasure and sustainability.

DSC and Dynamic Damper Control

The high-end chassis and suspension technology of the BMW i8 is based on a double-track control arm front axle and a five-link rear axle, whose aluminium components and geometry are specially configured for intelligent weight savings. The electromechanical power steering offers easy manoeuvring in town and typical sports car-style high-speed steering precision. Also standard is Dynamic Damper Control: the electronically operated dampers change their characteristics according to the selected driving mode to deliver the desired vehicle dynamics.

The DSC (Dynamic Stability Control) stability system includes the Anti-lock Braking System (ABS), Cornering Brake Control (CBC), Dynamic Brake Control (DBC), Brake Assist, Brake Standby, Start-Off Assistant, Fading Compensation and the Brake Drying function. The push button-activated Dynamic Traction Control (DTC) system raises the DSC thresholds, allowing some controlled drive wheel slippage for easier start-off on snow or loose ground, or for extra-dynamic cornering.

Full Spec Sheet & Stats

| type | Series Production Car |

| released at | 2013 Frankfurt Motor Show |

| built at | Germany |

| engine | Inline-3 w/Electric Motor |

| aspiration | Twin Turbo |

| displacement | 1499 cc / 91.47 in³ |

| power | 269.9 kw / 362 bhp |

| specific output | 241.49 bhp per litre |

| torque | 570 nm / 420.4 ft lbs |

| driven wheels | Hybrid 4WD |

| front tires | 195/50 R20 |

| rear tires | 215/45 R20 |

| front wheels | F 50.8 x 17.8 cm / 20 x 7 in |

| rear wheels | R 50.8 x 19.1 cm / 20 x 7.5 in |

| dry weight | 1490 kg / 3285 lbs |

| wheelbase | 2800 mm / 110.2 in |

| length | 4689 mm / 184.6 in |

| width | 1942 mm / 76.5 in |

| height | 1293 mm / 50.9 in |

| transmission | 6-Speed Automatic |

| top speed | ~250 kph / 155.25 mph |

| 0 – 100 kph | ~4.4 seconds |

| drag | 0.26 Cd |

| combined fuel econ eu | 2.5 L/100 km or 94.09 mpg-us |

| emission | 59 g/km |